Trip to Verla Mill Museum

Vol 27, Issue 1, 13 September 2024

Recently, students have had a chance to visit a UNESCO World Heritage Site in Finland. As there are only seven World Heritage Sites in Finland, it was a unique opportunity to see one of them. The site is a 32-kilometre drive from the city center of Kouvola, which takes 30 minutes by car or bus. The museum is located in the village of Verla. Back in the late 19th century the village flourished with people, work, and woods, but nowadays, the population of the village is nearly 30 people.

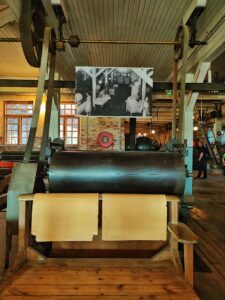

The groundwood mill was founded in 1872, and since then it has been developing and growing. The mechanisms of wood processing are quite complicated, and all processes are connected with one another.

On the first floor, there is a machine for peeling wood. Three men worked with that machine. One of them had to bring and clean woods, the other one had to cut them in smaller pieces and the last one had to place wood onto a rotating blade to polish it. Men only used thin gloves, so they had to be very careful with these operations. In general, people only used spruce in the mill, because they could get a high-quality product from it.

After polishing wood, it has been transferred to the next stage, which is grinding. They did not use any chemicals here, it was just fiber and water, so it is actually a pure product. Using only one machine, men could make 60 cubic meters of spruce. The idea is that fiber and water together would flow and transfer the mixture downstairs, which is the next stage.

Downstairs is actually a woman working place, which is another interesting fact because 40% of workers in the mill were women. With the machines downstairs, they produced thin layers of wood, which were then cut and taken into piles. This work required a lot of strength because on top of each pile women pressed a metal sheet, so that the layers would be flat.

Then those wet, thin layers of wood were transferred to another building. Originally the construction was wooden, but in 1893 it burned down, and they built a new one in just 3 months using red bricks. This building is called a drying loft. Those wet sheets were transported here in order to dry them. The drying loft could include 20000 of bordsheets. People used to heat the building, and the temperature inside could be 50 degrees, so it was like a sauna there. They could not stand working in such conditions for too long, so they used to cool themselves down in the swimming pool nearby.

The last, but not the least, stage is the sorting room, that is located upstairs in the drying loft. As the bordsheets were dry, women here scaled them and sort according to their weight. People of the mill made book covers, cigarette boxes, card boxes, boxes for sweets or even ammunition boxes from those bordsheets. Then they exported the ready products abroad, mostly to Russia, Great Britain, and even to the United States.

Once a historian visited the mill and was so impressed by the work they were doing that he decided to film a documentary video, take photographs, and interview workers in order to record this unique place. In 1997 Verla Mill became a UNESCO heritage site for its uniqueness, strong community, and connection with the forest. The mill made over 150000 tons of sheets in 80 years.

However, if you are not into history and long tours, there is still a huge chance for you to enjoy Verla Mill! You could take a walk near the river, take a look at famous Verla rock paintings, visit shops, climb up to Verla Giant’s Kettle, or just make a picnic with your friends! Do not miss a chance to visit one of the Finnish UNESCO World Heritage Sites!

- BIP in Poland: part 2 - 25th April 2025

- BIP in Poland: part 1 - 17th April 2025

- How to take breaks properly - 4th April 2025